Production Scheduling Software: Improve Manufacturing with Visual Planning

For production to be efficient, regardless of the type of goods produced, several aspects must be considered: manufacturing order planning, resource management, time management, resource allocation, and more.

96% of Visual Planning users believe they save time using our production scheduling software compared to their past strategy!

Why Choose Visual Planning?

5000+ companies are using Visual Planning worldwilde to schedule more efficiently.

Scheduling is crucial for any company managing diverse and complex production operations. To effectively oversee these operations, various features are needed to simplify user understanding, track changes (such as delays or modifications in production plans), and schedule the use of available materials, machinery, and resources. Our clients choose our production management software for its ability to centralize all production data. With a comprehensive scheduling system that integrates resource management, process management, inventory management, production order planning, and many other features, your production manager will have all the tools necessary to make informed decisions and enhance efficiency.

What is Production Scheduling Software?

Production Scheduling Software is a specialized tool designed to help manufacturers and production managers plan, schedule, and optimize their production processes. It assists in managing and coordinating various aspects of production to ensure efficiency, minimize downtime, and maximize resource utilization. The software allows for the allocation and management of resources such as labor, machinery, and materials to different production processes. It enables the creation of detailed production plans that outline the sequence of operations, timelines, and deadlines for manufacturing products. Scheduling capabilities help determine when and how production processes will be executed, considering factors such as machine availability, labor shifts, and order priorities.

Additionally, the scheduling software helps track inventory levels of raw materials, work-in-progress, and finished goods to ensure materials are available when needed. It provides real-time visibility into the production process, allowing managers to monitor progress, identify bottlenecks, and make necessary adjustments. Production orders are managed from initiation to completion, with tracking of order status, deadlines, and delivery schedules. Workflow automation reduces manual intervention and increases efficiency, while analytics and reporting generate insights on production performance, resource utilization, and other key metrics to support data-driven decision-making.

Benefits of Production Scheduling Software

To optimize productivity, improve customer satisfaction, and enhance employee satisfaction, it is essential to integrate all the processes within your production chain. Choose scheduling software that can incorporate all the information from your operations and adapt to your evolving needs!

Implementing a Scheduling System

Production planning is crucial for avoiding delays and bottlenecks. By anticipating the need for resources such as raw materials, equipment, and personnel, you can optimize processes and ensure smooth work order execution.

Maintaining the Quality of Your Production

Maintaining high standards of quality throughout the production chain is essential for customer satisfaction and the company’s reputation. By planning and regularly conducting rigorous quality checks at each stage of your production processes, you can ensure that the finished products meet the required specifications.

Resource and Inventory Management

Optimize the use of your human & material resources through effective management of your needs. By wisely allocating your employees and equipment based on their skills, qualifications, and availability, you will avoid bottlenecks and maximize the efficiency of your production.

Avoiding Delivery Delays

Avoiding delivery delays is crucial for maintaining customer trust. To ensure timely deliveries and enhance customer satisfaction, you need to carefully plan all operations from procurement to shipping, identify potential risks and production errors, and anticipate logistical issues.

How it works?

To configure your production scheduling software to accommodate any production management methodology, Visual Planning’s team has developed a tailored five-step approach, including; 1) Requirement Analysis, 2) Design & Configuration, 3) Testing & Validation, 4) Implementation, 5) Evaluation & Improvement.

1) Requirement Analysis

During your first interaction with one of our sales representatives, we will assess your needs to better understand your business challenges and scheduling requirements.

Learn More

During a customized demo tailored to your specific production management needs, we will showcase the Visual Planning features most relevant to your production processes. Following this, our consulting team will review and confirm the functional scope and feasibility of your requirements. We will then provide you and your team with an estimate for the implementation timeline, training, and overall deployment.

2) Design & Configuration

Based on your functional scope, we will assign one of our in-house consultants to work with you, in which he/she will gather all the necessary information about your manufacturing needs to configure your scheduling software effectively.

Learn More

Your operational team will collaborate with our consultant to oversee the implementation of Visual Planning and validate its progress throughout the project. We focus on delivering various outputs during the project and use an agile methodology to ensure you receive the most valuable solution for your production management needs.

3) Testing and Validation

Take advantage of our native import/export features to load all your current data into your production scheduling solution before going live.

Learn More

Your operational team will collaborate with our consultant to oversee the implementation of Visual Planning and validate its progress throughout the project. We focus on delivering various outputs during the project and use an agile methodology to ensure you receive the most valuable solution for your production management needs.

4) Implementation

Once your entire scheduling process has been tested and approved, you will be ready to use Visual Planning to schedule your production orders.

Learn More

Features of our software, such as our filtering system and user-friendly interface, will enable you to assign the most suitable resources to your production orders while monitoring your overall activities, and much more!

5) Evaluation and Improvement

Your sales representative will remain in contact to assist with any necessary adjustments to your production scheduling solution, accommodating your company’s growth and daily challenges.

Learn More

Whenever needed, you can reach out to our team for support with adding access to your configuration, incorporating missing features, or obtaining technical assistance.

Automated Features with Visual Planning for Production Management

Visual Planning 9 is now available and comes with new features. Among these, you’ll find “VPAutomation”, which includes two new sets of automation: automatic scheduling and automatic allocation!

Automatic Scheduling in Production Scheduling

“VPAutomation’s” scheduling feature allows for the automatic planning of process sequences based on the availability and specific skills of each resource. By integrating this tool, you can optimize resource allocation, ensuring efficient use of time and skills. Ideal for production management, regardless of the type of production, the product, or your production processes, this tool can also be used for generating your business schedules.

Learn more

“VPAutomation” takes various variables into account to maximize your schedule. Some of these variables may be mandatory, while others can be optional, providing great flexibility. Among these variables are manufacturing routings, which define the necessary production steps for creating a product. Machine speeds are also considered, optimizing the production capacities of available equipment.

Additionally, temporal variables can be integrated to ensure deadlines are met. Process priority can be configured, ensuring that the most critical processes are addressed first by the scheduling algorithm. This comprehensive and detailed approach allows for precise and effective planning, tailored to the specific needs of each production process.

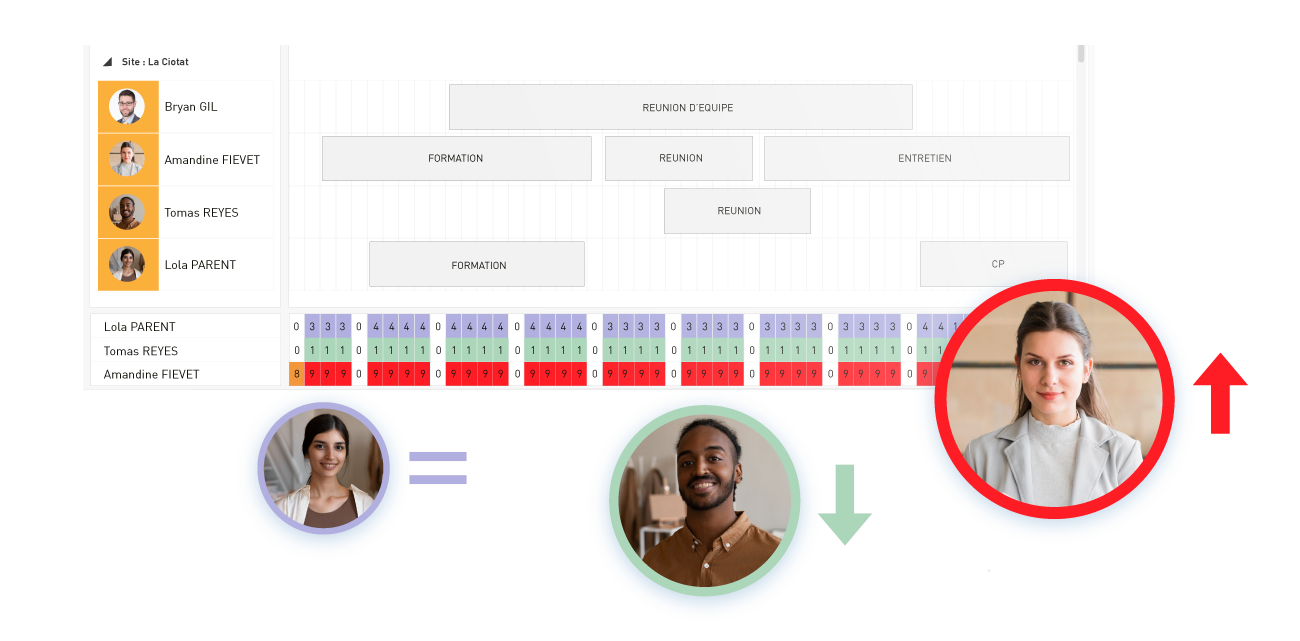

Auto-assignment in Production Scheduling

“VPAutomation’s” auto-assignment algorithm now enables the automatic assignment of your resources to existing shifts (schedule events) based on their availability and specific skills. This system allows for more precise and personalized management of your personnel. It also incorporates the ability to adhere to your own human resource management rules. For example, it considers working time contracts (such as 35-hour or 39-hour workweeks) and mandatory rest periods, such as breaks between shifts.

Learn more

The implementation of “VPAutomation’s” automatic scheduling and automatic allocation algorithms is greatly simplified and facilitated by our API Designer, integrated with Visual Planning. The goal is to easily adapt these automation features to your specific contexts. This enables you to easily create schedules, optimize resource management, and make your production process more efficient!

Discover the Other Key Features of Visual Planning’s Production Scheduling Software

Automation features for production scheduling are not the only tools that can enhance your productivity. Below, discover other key features for managing your resources, schedules, and much more!

Visualize Your Production the Way You Want

Once our Visual Planning software is configured for your production management, it will specifically streamline and optimize logistics by considering the constraints and impacts of your order management, workflow management, production times, inventory management, and more on your production organization.

Learn more

Moreover, our production scheduling tool will enable you to plan and track your activity from the initial stage to customer delivery. To achieve this, a range of views can be configured and customized according to your needs: schedules, Gantt charts, Kanban boards, blueprints, and more.

Drive Your Production Scheduling with Load Plans

By integrating all information about your human and material resources (availability, skills, maintenance, usage, etc.) and using tools like Load Plans, Constraints, and Control Totals, you will gain real-time visibility into your operations and how well your workload aligns with your capacities.

Learn more

By integrating your own management rules and business constraints, you will reduce the risks and/or delays in production (such as resource unavailability, double booking of a resource, stock shortages, etc.). Moreover, this real-time visibility will allow you to anticipate periods of overload or underload, enabling you to adjust your schedules, seek external resources, reschedule certain operations, and more.

Manage Your Costs to Improve Your Gross Margin

The identification and management of labor & material resource costs are consolidated at the global level of your production chain, allowing you to better manage allocated or available budgets. Indeed, all the insights provided on your resource schedules, load plans, and availability can include cost factors, enabling you to fine-tune your processes for optimal production efficiency.

Visual Planning will enable you to track the evolution and performance of your production chain in real time. This capability allows you to instantly communicate any changes in production strategy to your teams!

Centralize All Your Data Within Your Production Scheduling Software

Once a new production order enters your production management software, it is essential to provide your teams with all the relevant information needed to deliver a product that meets customer requirements and expectations.

Learn more

To achieve this, Visual Planning allows you to centralize all your information (specifications, purchase orders, delivery notes, procurement details, bills of materials, etc.) through a resource database within your software or by accessing processes in your schedule via various displays & views. Moreover, with a permissions & user rights management system, you can provide differentiated access for each user profile. You can even create restricted access for external users, such as clients or suppliers. The goal is to prevent information loss, duplication, and tedious searches for data.

Integrating Visual Planning into Your Information System

Integrating Visual Planning into the core of your information system aims to elevate your production management to a new level. This will provide you with a fully seamless production management system. To create the necessary interfaces between Visual Planning and your other systems, you can use our import/export features as well as our API.

- The configurable standard import and export features support formats such as XLS, CSV, XML, and JSON, and can handle manual, scheduled, automatic, or external triggers. These features are both easy to implement and highly powerful.

- The REST API, available free of charge, includes all the methods necessary for your interfaces. Web services using this API can be developed by our team or your own IT department. For instance, some Visual Planning users have leveraged the API to create data exchange interfaces with their ERP, MRP, CMMS, MES, HR systems, and more.

Learn more

Beyond these interfacing developments, Visual Planning also offers Webviews that allow you to integrate specific elements into its interface from your context or any external application. Among the tools you can interface with in a production management context are SAP, CEGID, SAGE, MS Business Central, Sylob, Clipper, TopSolid, and others.

What our users are saying

Frequently Asked Questions

Why Use Scheduling Software in Manufacturing?

Scheduling software in manufacturing is essential for optimizing resource use and ensuring work orders are delivered on time. It allocates machinery, labor, and materials effectively, minimizing downtime and maximizing productivity.

By providing real-time updates and detailed planning capabilities, the software helps in managing production schedules, reducing lead times, and coordinating resources. This enhances visibility into operations, allowing for quick adjustments and improved response to changes in demand. Additionally, it supports efficient inventory management, aligning material supply with production needs, and prevents shortages and excess inventory.

The software also fosters better communication between departments, leading to more coordinated efforts and cost savings. Overall, scheduling software improves operational efficiency, reduces costs, and enhances customer satisfaction.

What is the Best Production Scheduling Software?

To determine the best production scheduling software for your needs, start by identifying your requirements and priorities:

- What type of production do you manage? How many users will need access?

- What specific features are essential? Is the software user-friendly?

- Do you require integration with your existing systems?

By answering these questions, you can create a functional scope and list of requirements to guide your selection process. Users managing their production activities with Visual Planning often choose our software for its flexibility and ease of use. It offers a comprehensive overview of various work orders, including timelines, client histories, and administrative documents, and provides mobile access to information from anywhere.

Who Benefits from Production Planning Tools?

Any company, whether a small or medium-sized business (SMB) or a large enterprise, can benefit from production scheduling software. Its value extends to every employee, from production managers and operators to engineers and plant managers.

For example, a site supervisor needs an immediate overview of all ongoing work orders to effectively allocate processes, manage resources, and oversee budgets. On the other hand, workers benefit from visibility into their own operations, assigned work orders, and personal data.

Providing tailored access to data based on roles—whether production managers, plant managers, operators, or engineers —is crucial for successful production management. In summary, every individual involved in the production process will gain from using the scheduling tool.